How DoKaSch helps space project Einstein-Probe to move sensitive components

DoKaSch is moving sensitive optical satellite components of the Einstein-Probe mission that will analyze changing cosmic objects within the x-ray spectrum and aims for deeper insights into the origins of black holes or the very first stars of the universe.

DoKaSch Temperature Solutions is supporting four transports of telescope components for the Einstein-Probe satellite, a mission of the Chinese Academy of Sciences with a contribution from the European Space Agency (ESA), from Germany to China with its Opticooler containers to protect sensitive optical satellite components.

Space missions require extensive preparations which include specialized logistics solutions in order to ensure that the often highly sensitive components stay intact at all times. For DoKaSch, this series of transports shows the value of the Opticooler containers beyond pharmaceutical transports.

Andreas Seitz, managing director at DoKaSch Temperature Solutions, explains the importance of the project, “We have designed and established our containers as the most reliable solution for temperature-sensitive products. When the Max-Planck Institute inquired about using our Opticooler for the Einstein-Probe components, we saw this as a chance to demonstrate the versatility of our products in other fields. Specialized transports like this one often require precise temperature ranges and a high level of reliability, which makes our Opticooler the ideal solution. It is a very unique project and we are proud to contribute to do our part for the exploration of the universe.”

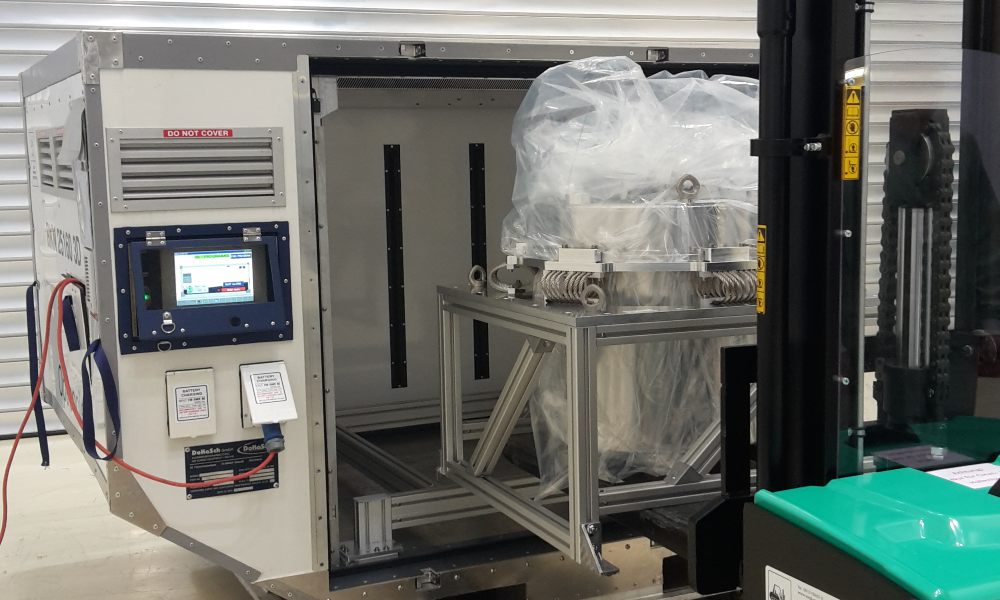

Some of the components are built by the Max Planck Institute for Extraterrestrial Physics (MPE) in Munich, Germany, due to their experience with similar missions. In 2019, a space probe with a similar range of tasks was launched in the eROSITA mission, in which MPE is participating. “Together with DoKaSch and a forwarder, the institute designed a unique transport solution for the components which fits in an Opticooler RKN, a temperature-controlled air cargo container (ULD),” informed Seitz.

The special optic of the X-ray telescope is protected in a case with the approximate size of a 30-litre barrel.

The Einstein-Probe mission is analyzing changing cosmic objects within the x-ray spectrum and aims for deeper insights into several key questions in astrophysics and cosmology, like the origins of black holes or the very first stars of the universe. The key instruments of the satellite are two telescopes. For one of them, the MPE provides several key components. One of them is the mirror assembly of the telescope, which focuses on the incoming x-rays. In total, four versions of the module are required to be transported for the project.

The first one was a dummy without any functions, which is used to ensure all measurements are correct and the module fits into the satellite together with the other parts. The second version had limited set functions and was used to conduct first functionality tests of the telescope.

The third and fourth versions of the mirror assembly are called “flight-ready” by the MPE, which means they are fully functional and ready for space flight. While the third model will be used as a reference model on earth in case of problems, the fourth and final version will be launched into space with the satellite.

DoKasch informed The STAT Trade Times that the first three transports from the MPE in Munich to Beijing have already been accomplished and the fourth one will take place in 2022. “While not all the transported modules were the same in their functionality, they all required the same level of preparation and careful handling, which is why each transport must be conducted flawlessly,” noted Seitz.

The mirror assembly is sensitive to contamination, large temperature variations and mechanical shocks. It is therefore packed in a clean sealed stainless steel container with pressure compensation and wrapped additionally in foils with a clean atmosphere. The cylindric steel container is fixed in a damping frame that absorbs shocks during transport and loading. The upper part of the damping frame with the protected goods is screwed to the lower part that acts as an adapter to the air cargo container.

The special optic of the X-ray telescope is protected in a case with the approximate size of a 30-litre barrel. Inside, fixed in a spoke wheel, there are 54 thin nested tubular mirrors with gold coating for maximum X-ray reflectance. This so-called mirror assembly will later be mounted into the satellite where an X-ray camera is placed at a 1.6 m distance where the focus lies.

MPE approached DoKaSch Temperature Solutions as the institute required a temperature-controlled solution that could ensure stable temperature levels of around 20°C for the duration of the transport and provides enough space for a transport rig. For the transport, the mirror assembly had to be packed into a box, which has a diameter of 650mm, is about 700mm high and weighs 100 kilograms. Furthermore, a custom-made dampening rig had to be built into the transport solution to prevent vibrations and jolts.

Seitz said, “DoKaSch’s Opticooler RKN proved to the ideal solution for this purpose. It does not only provide temperature control but it can also be transported on scheduled flights due to its standardized measurements. In turn, DoKaSch and the MPE partnered up for this special transport project. Since DoKaSch has extensive experience in manufacturing air cargo equipment and could advise on the design for the rig, both partners found a fitting and reliable solution to ensure a flawless transport process.”

The project called for a variety of different solutions for the transport process and especially the security check, which is usually conducted at the airport, proved challenging. Since the mirror assembly must be packed and unpacked under cleanroom conditions, it had to be loaded into the Opticooler at the MPE. Afterwards, the Opticooler cannot be opened before it arrives at the laboratory in China. However, the metal box for the module renders x-ray security scans useless. In turn, it was not possible to conduct a security scan in Bejing after the arrival of the cargo. Therefore, the security check procedure had to be conducted at the MPE before departure. For that purpose, a special permit from the German Federal Aviation office was required.

“This special matter was handled by the forwarder, who was already experienced with unique transports like this one. Customs procedures also required extra planning. While the mirror assemblies remained in Bejing, the Opticooler had to be brought back to Germany together with the transport rig after every transport. Since the satellite component, the rig and the container itself were categorized differently by customs, it was challenging to ensure smooth import- and export customs procedures. Due to a close collaboration of all the participating partners together with the Chinese authorities, a solution was found which guaranteed flawless transport processes for both ways,” Seitz added.

(Photos: Max Planck Institute for extraterrestrial Physics, Munich)