The logistics that drive the Super Bowl halftime

Inside the time-critical supply chain, staging and people power that delivered a global halftime spectacle.

Source: wired.com

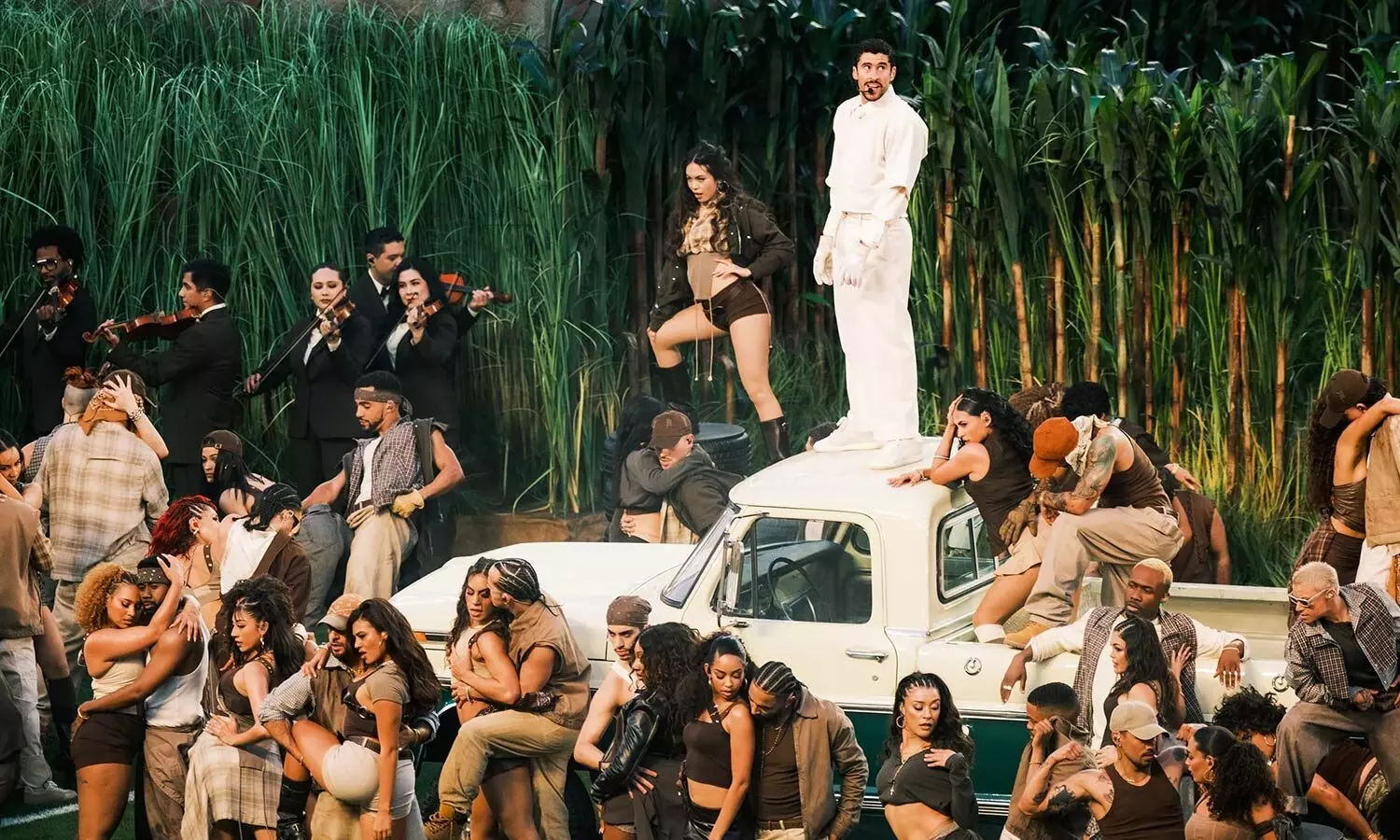

When Bad Bunny took the Super Bowl halftime stage, the world saw rhythm, spectacle, and flawless timing. What most never see is the industrial-scale logistics operation that powers those 13 minutes, a system so precise that a single missed cue could derail a broadcast watched by over 100 million people.

Unlike a concert tour that builds over days, the Super Bowl halftime show is installed, rehearsed, performed, and dismantled within one of the most unforgiving timelines in live entertainment. From the moment the second quarter ends, the field becomes a moving factory.

The halftime show is produced by the NFL in partnership with Roc Nation and Jesse Collins Entertainment, working with broadcast networks, stadium authorities, unions, and specialist logistics contractors. The artist defines the creative direction, but the delivery is powered by a global event production ecosystem.

Source: wired.com

Behind the scenes, the human movement was as complex as the freight flows. In total, 2,000 to 3,000 people were involved across the operation, including performers, choreographers, stagehands, riggers, broadcast engineers, safety teams, logistics coordinators, and security personnel. Hotels, transport corridors, access routes, and credential systems were pre-mapped so every individual arrived at the right door, at the right minute.

The supply chain itself was global. Lighting systems arrived from Europe, audio and control systems from North America, custom scenic elements from regional fabricators, and wardrobe from specialist studios. All shipments moved under ATA Carnets were tracked in real time and routed through secure holding facilities before final delivery to the stadium.

Weather contingencies, power redundancy, alternate routing, backup show files, and emergency teardown scenarios were built into the logistics plan. Every risk was simulated. Every failure point was mapped.

The scale of the operation is matched by its cost. The modern Super Bowl halftime show typically carries a production budget of USD 13–18 million, or roughly USD 1 million per minute of performance. The 25-cart limit was introduced for this Super Bowl after the NFL tightened its field and event-safety regulations following recent reviews of turf damage, player injury risk, and broadcast congestion linked to halftime productions.

Modern stadium pitches now sit on layered systems that include shock-absorption pads, heating and drainage lines, and in-ground tracking sensors, making them far more sensitive to heavy rolling loads. With a fully loaded stage cart weighing close to a tonne, league operations teams concluded that allowing more than 25 carts on the field at one time would risk surface deformation and delay the post-halftime safety clearance required before play can resume. The rule also protects broadcast camera lanes and emergency access routes, which had become increasingly restricted as halftime sets grew larger. As a result, the NFL enforced a fixed, non-negotiable cap this year, forcing production teams to redesign their entire logistics plan around just 25 mobile platforms.

Source: wired.com

At the two-minute warning before halftime, pre-positioned carts carrying modular stage platforms roll onto the field from multiple tunnels. Every unit is color-coded, weighted, and pre-wired. Crews know exactly where each piece must land, down to the inch.

In less than seven minutes, the field is transformed into a concert venue. LED floors lock into place. Power, audio, and fiber lines are connected through quick-release systems. Broadcast cameras are reprogrammed. Lighting towers rise. All of this happens while referees, broadcast teams, and stadium security continue operating around them. Nothing arrives by chance. Every crate is packed in reverse order of use. Every cable is pre-labeled. Every failure point has a backup.

The halftime performance may look like entertainment, but operationally, it runs more like a military drill. Equipment is shipped weeks in advance through a secure, bonded supply chain. Customs clearance, freight staging, and last-mile trucking are coordinated to the hour. Redundant power generators, duplicate lighting consoles, and backup audio systems are positioned off-field in case of failure.

Once the performance ends, the clock resets. Crews have just minutes to clear the field before the third quarter begins. Platforms are unlocked, cables disconnected, and carts rolled back into tunnels all in reverse order of installation. By the time play resumes, there is no sign that a concert ever happened.

The artist may stand in the spotlight, but the real stars of the halftime show are the planners, freight teams, riggers, stagehands, broadcast engineers, and logistics coordinators who make the impossible routine.

Bad Bunny’s performance was unforgettable. But behind those 13 minutes was a supply chain so disciplined, so rehearsed, and so unforgiving that it proves one thing: At the Super Bowl, the biggest show in the world is not just on stage; it is in the logistics.